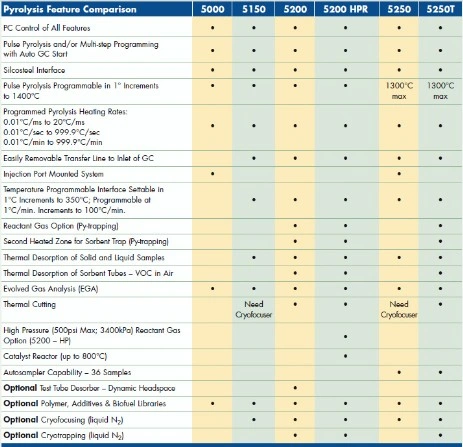

Pyrolysis Systems from CDS Analytical

Products > Analytical

Pyrolysis is the process of applying heat to large, complex molecules in order to break them into smaller, more analytically useful fragments. When coupled with GC, GC/MS, Direct MS, or FTIR, pyrolysis enables quantitative and qualitative analysis of vastly divergent sample types, without lengthy extractions or derivatizations. Many organic solids are unsuitable for analysis by any other means.

CDS 5000 Series pyrolyzers set the standard of excellence for quality construction and advanced functionality. These sturdy, durable instruments are designed for easy upgrading, meaning your instrumentation investment is always protected and can be leveraged as and when your requirements change.

Top Features of the leading edge technology

- Multi-Step Runs allow you to analyze volatiles before pyrolyzing the actual sample (up to 8 GC runs per sample)

- Platinum filament pyrolyzer for pulse, and multi-step, programmed pyrolysis

- Three, User-Selectable Operation Modes: Run, Dry, Clean

- Simplified sample loading with cost-effective quartz probe tubes

- Easily convert to Thermal Desorption operation with TD-Tubes

- Programmable interface with Windows-based PC Control

- Interfaces directly to injection port or with heated transfer line

- Compatible with GC's from different manufactures

- Optional trapping zone for Reactant Gas Operation (enables Pyrolysis under Air/Oxygene atmosphere)

- Optional slow rate Pyrolysis with trapping

- Optional Catalyst Reactor

- Optional High Pressure Operation (max. 34 Bar/500 psi)

- Optional AutoSampler with 36 sample tray (5250T series)

High Pressure Pyrolyzer with Micro Catalyst Reactor

CDS Analytical has introduced the first micro high-pressure pyrolysis reactor system 5200HPR. Scientists studying new biomass feed stock, coal, oil or polymer reactions need to understand how these materials break down in a reactor at varying conditions with catalysts. The high-pressure pyrolyzer allows them to study both high temperature & pressure on a small scale while passing the pyrolyzed gas through a catalyst bed.

And in addition, the background gas can be GC carrier gas or a reactant gas such as air, hydrogen or oxygen. Samples can be pyrolyzed at elevated pressures (34BAR/500PSI max) and passed through a catalyst bed of their choice and then collected onto the built-in trap. After pyrolysis of the sample is complete, the analytes are transferred from the trap to a GC at normal operating conditions. This instrument will retain all the features of the standard 5200 system and can be used as a normal pyrolyzer too.

Customized Pyro/FT-IR Coupling

Special Brill Cell FT-IR Interfaces for the integration into different spectrometers brands are available by Intelli. Pictures on the right show an integration into a Bruker Tensor FT-IR spectrometer as an example. The Brill Cell is installed in the sample compartment of the FT-IR so that the Pyroprobe filament is positioned just below the light path. All 3-axes are fine adjustable to maximize the light transmission through the cell. The cell itselfs is heated by the interface control of a standard 5200 Pyroprobe and is purged to vent automatically. Automated control of the Pyrolyzer together with automatic cell purge is embedded into the Bruker OPUS software.